Rattan, A home With Style

Indonesia is the largest producer of rattan in the world. Almost 80 percent of rattan plants are found in Indonesia, mainly spreading in 15 provinces in Sumatra, Kalimantan, and Sulawesi, with a production capacity of around 700,000 tons annually. There are many kinds of rattan found in Indonesia. Based on the size, Indonesian rattans are divided in two groups: a group with large diameter and a group with small diameter.

Indonesia’s rattan furniture products have been exported to more than 200 countries around the world. Fifteen major markets in were: United States, Germany, Japan, United Kingdom, Netherlands, Italy, Spain, Belgium, France, Australia, Malaysia, Greece, Russia, South Africa, and Singapore.

In the large diameter group there are: "Manau", "Batang", "Tohiti", "Semambu", "Tabu-tabu", "Ambulu", and "Suti". While in the small diameter group there are "Sega", "Pulut", "Cacing", "Jahab", "Air", and "Dalu".

The uses of rattan vary, among others are:

- Round rattan is used for frame of chairs tables, stands, umbrella sticks, etc.

- Rattan peel is used for webbing of mats, mattress, bags, baskets, etc.

- Rattan core is used for various household articles.

- The waste of rattan industry still can be used as material for fire cracker industry, etc.

- Rattan can be used for various luxurious purposes including luxurious furniture, weaving products for household needs, as well as wall surface decoration, isolator against cold weather, and so on.

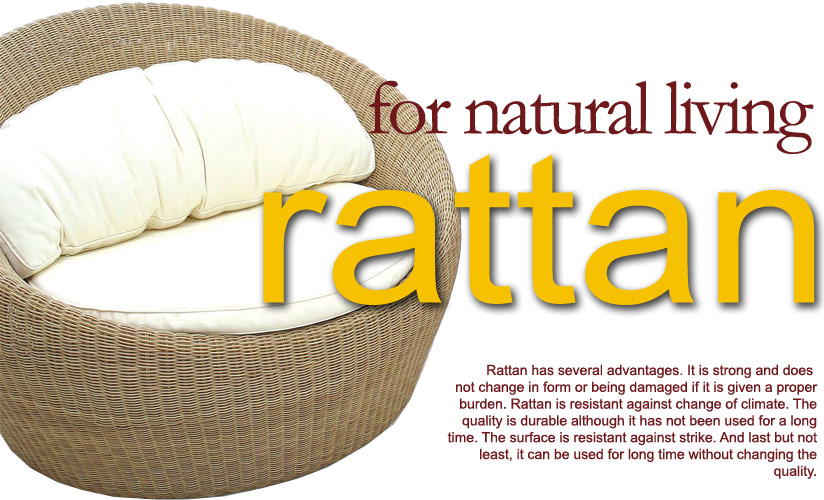

Rattan has several advantages. It is strong and does not change in form or being damaged if it is given a proper burden. Rattan is resistant against change of climate. The quality is durable although it has not been used for a long time. The surface is resistant against strike. And last but not least, it can be used for long time without changing the quality.

Rattan is the name for the roughly hundred species of palms in the tribe Calameae, native to tropical regions of Africa, Asia and Australasia. Most rattans are distinct from other palms in having slender stems 2–5 cm diameter with long internodes between the leaves; their consequent growth habit also differs, not being trees but vine-like, scrambling through and over other vegetation.

They are also superficially similar to bamboo, but distinct in that the stems (“malacca”) are solid, rather than hollow, and also in their need for some sort of support; while bamboo can grow on its own, rattan cannot. Many rattans are spiny, the spines acting as hooks to aid climbing over other plants, and also to deter herbivores.

Rattans have been known to grow up to hundreds of metres long. Most (70%) of the world’s rattan population exist in Indonesia, distributed among Borneo, Celebes, Sumbawa islands.

In the forests where rattan grows, its economic value can help protect forest land, by providing an alternative to loggers who forgo timber logging and harvest rattan canes instead. Rattan is much easier to harvest, requiring simpler tools and also much easier to transport. Furthermore, compared to most tropical wood, rattan is much faster growing. This makes it a potential tool in forest maintenance, since it provides a profitable crop that depends on rather than replaces trees. Whether it can be as profitable or useful as the alternatives, however, remains to be seen.

Generally, raw rattan is processed into several products to be used as materials in furniture making. The various species of rattan ranges from several millimetres up to 5–7 cm in diameter. From a strand of rattan, the skin is usually peeled off, to be used as rattan weaving material. The remaining “core” of the rattan can be used for various purposes in furniture making. Rattan is a very good material mainly because it is lightweight, durable, and—to a certain extent—flexible.

Rattans are extensively used for making furniture and baskets. Cut into sections, rattan can be used as wood to make furniture. Rattan accepts paints and stains like many other kinds of wood, so it is available in many colours; and it can be worked into many styles. Moreover, the inner core can be separated and worked into wicker.